FERRO SILICA IRON POWDER

Promine, yoğun ortam atomize ve öğütülmüş Ferrosilisyumun küresel tedarikinde, It is well-positioned to provide quality products to the mining and metal recycling industries. Ferrosilicon supply is widely used in heavy-medium separation processes where separation is performed based on the relative density difference between the materials to be separated.

PRODUCTS

DMS ferrosilikon, plaka çeliği ve %75 FeSi’nin parti prosesinde eritilmesiyle üretilir. Atomize ürünler, istenen boyut dağılımına kadar su atomizasyonuyla atomize edilir. Öğütülmüş ürünler ise iri taneli hale getirilir ve ardından istenen boyut derecesine ulaşmak için öğütülür. Üretim süreci, doğru kimyasal ve fiziksel özelliklerin elde edilmesini sağlamak için titizlikle kontrol edilir.

Atomize Ferrosilisyum:

Coarse, Fine, Extra Fine, Cyclone 60, Cyclone 40

Ground Ferrosilicon:

65D, 100D, 150D, 270D, 270F Strict quality control procedure.

When used, it ensures compliance with our technical specifications by exhibiting the following characteristics:

- The desired specific gravity can be obtained.

- Corrosion resistance

- Wear resistance

- Magnetic properties that allow for easy recovery and demagnetization.

- Cost-effective

Each solution is sampled and tested for accurate chemical analysis. The final product is also sampled and tested. A batch number is assigned to ensure traceability. Product samples are also tested and verified by independent laboratories.

TECHNIQUE

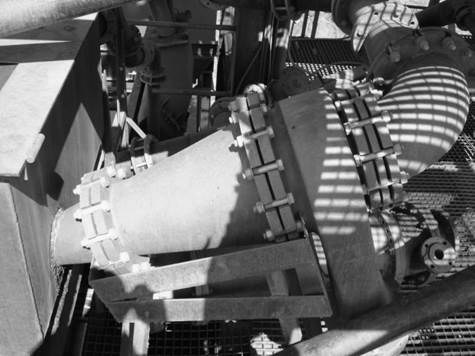

Ferrosilicon is used to create a concentrated medium by mixing it with water, and separation takes place in a static (drum) or dynamic (cyclone) separation unit.

Bu operasyon, Ağır Ortam Ayırma veya Batırma-Yüzdürme İşlemi olarak da bilinir. Ayırma işlemini gerçekleştirmek için sertlik, renk, şekil, elektrik, manyetik, yüzey, radyoaktivite veya yoğunluk gibi farklılaştırıcı davranışa neden olan fiziksel özelliklere sahip olmak gerekir . Ayrılacak ürünlerin yoğunluk farkından yararlanılarak metallerin geri kazanıldığı madencilik ve metal geri dönüşüm endüstrilerinde iyi bilinen bir işlemdir.

Dense medium separation is a process used to separate particles of different densities in a medium consisting of water and heavy solids (suspension). In this suspension, heavier particles sink, while lighter particles float.

Ferrosilicon suspension consists of water and ferrosilicon powder. Ferrosilicon powder has a relative density of 6.7-7.1 g/l and contains 14-16% silicon.

Both the physical and chemical properties of ferrosilicon contribute to separation efficiency and media recovery. Therefore, maintaining the quality of ferrosilicon and selecting the correct grade for the application is crucial.

Ferrosilikon süspansiyonunun önemli özellikleri, ortam yoğunluğu, viskozite ve kararlılıktır.

The Dense Media Separation process consists of separation and media recovery circuits. Ferrosilicon properties are designed to maximize separation efficiency while optimizing media recovery.

Intensive media enrichment is a well-established process in the mining and metal recycling industries.

| Medium Density: The concentration of ferrosilicon solids in the medium. The medium density is increased by adding more ferrosilicon solids and decreased by adding water. The medium density determines at what density separation will occur. Medium Viscosity: Viscosity is a measure of a medium's resistance to flow. It is determined by the concentration, shape, and size distribution of the solids that make up the medium. A low viscosity is desirable for dense medium separation processes. High viscosity increases the likelihood of particle misalignment, thus reducing separation efficiency. Moderate Stability: The tendency of solids in the medium to settle. Since the relative density of solids is higher than that of water, the medium is inherently unstable. The inverse of the rate at which solids in the medium settle under gravity is a measure of the stability of the medium. Generally, a stable medium is desirable. As unstable media settle in pipes and pumps, density gradients can form in separators, reducing separation efficiency. |

Material Safety Data Sheet

Material-Safety-Data-Sheet